In today’s construction and utility industries, ensuring the safety of workers and preventing damage to underground utilities are paramount. One of the most effective tools in achieving this is the High-Visibility Detectable Warning Tape. This blog will provide a comprehensive overview of detectable warning tape, its uses, benefits, and why it is essential for any construction or utility project.

What is Detectable Warning Tape?

Detectable warning tape marks underground utilities, such as electrical lines, gas pipelines, water mains, and communication cables. Unlike regular marking tapes, detectable warning tape contains a metallic strip or layer, making it easily detectable by metal detectors, even when buried several feet underground. This makes it an essential safety tool in construction and excavation projects.

Key Features:

- High Visibility: The tape is available in bright colors like red, yellow, blue, and green, often combined with bold black lettering that indicates the type of utility buried below (e.g., “Buried Electrical Line,” “Gas Line Below”).

- Durability: Made from high-quality materials such as polyethylene, the tape is resistant to environmental factors like moisture, chemicals, and UV rays. This ensures that it remains intact and visible even after long periods underground.

- Ease of Detection: The embedded metallic strip allows easy detection using standard metal detection devices, preventing accidental damage to utilities during excavation.

- Versatility: Detectable warning tape is available in various widths and lengths to suit different projects and utilities.

Why is Warning Tape Important?

Detectable warning tape is not just a matter of good practice; safety regulations often mandate it. The tape serves as a crucial warning system to alert workers of the presence of underground utilities, helping to prevent accidents that could lead to costly repairs, service interruptions, and even severe injuries.

Preventing Accidental Damage:

Workers who are unaware of buried utilities risk damaging these lines during excavation. For instance, hitting a gas line can cause explosions, while severing an electrical line can lead to power outages and electrocution. Detectable warning tape provides a visible marker that prevents such incidents by ensuring workers know precisely where utilities are located.

Ensuring Compliance:

Many regulatory bodies require detectable warning tape for marking underground utilities. Compliance with these regulations is a legal requirement and a best practice demonstrating a safety commitment. Failure to comply can result in fines, project delays, and legal liabilities.

Reducing Project Costs:

Accidental damage to underground utilities can lead to significant project delays and additional costs for repairs and compensation. Companies can mitigate these risks by using detectable warning tape, ensuring that projects stay on schedule and within budget.

-

High-Visibility Safety Warning Tape – Red and White Stripe, 3-Inch x 300-Foot Roll | Ideal for Construction, Barricades, and Hazard Marking

-

Safety Rules Signage – Custom Printed Safety Signs for Workplace & Construction

Original price was: د.إ200.د.إ150Current price is: د.إ150.

Applications of Detectable Warning Tape

This warning tape is used in various applications across various industries. Below are some of the most common uses:

- Utility Marking:

Detectable warning tapes is widely used to mark the location of underground utilities, including:

- Electrical Lines: To prevent electrocution and power outages.

- Gas Pipelines: To avoid the risk of explosions and gas leaks.

- Water Mains: To prevent damage that could lead to water contamination or flooding.

- Communication Cables: To protect telephone, internet, and fiber optic lines from being cut.

- Construction Sites:

Construction projects often involve excavation, which can be risky if workers must be aware of buried utilities. Detectable warning tape helps construction teams identify and avoid these hazards, ensuring a safer work environment.

- Roadwork and Infrastructure Projects:

During roadwork or infrastructure development, it is expected to encounter buried utilities. Using detectable warning tape ensures that these utilities are appropriately marked, reducing the risk of damage during excavation or drilling.

- Landscaping and Irrigation Projects:

Landscapers and irrigation specialists often work with buried lines for water, lighting, and other utilities. Detectable warning tape helps them locate and protect these lines during installation or maintenance.

- Environmental and Remediation Projects:

In environmental cleanup and remediation projects, detectable warning tape marks areas with buried hazardous materials or waste, ensuring workers know potential dangers.

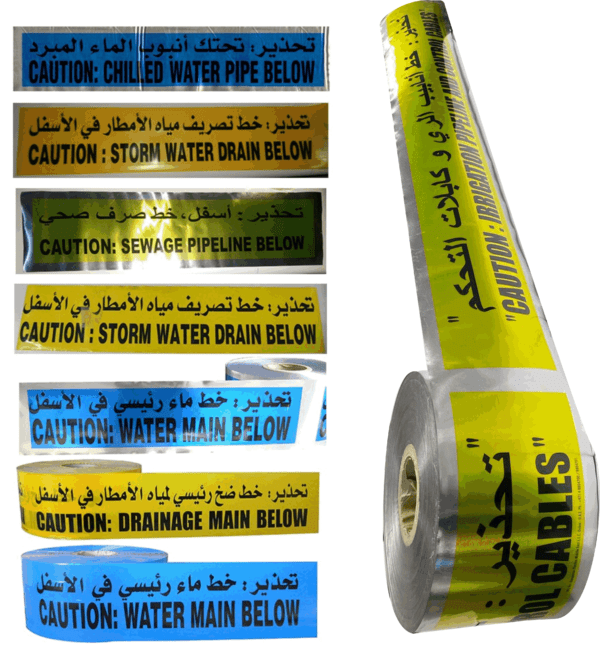

Types of Detectable Warning Tape

Various types of detectable warning tape are available, each designed to meet specific needs. Here are some of the most common types:

- Buried Electrical Line Caution Tape:

This type of tape is specifically designed to mark the location of buried electrical lines. It is typically yellow with bold black lettering and includes a metallic strip for detection.

- Gas Line Warning Tape:

Gas line warning tape is usually bright yellow or red and marked with warnings about buried gas pipelines. This tape helps prevent accidents during excavation or drilling near gas lines.

- Water Line Detectable Tape:

Water line detectable tape is often blue and used to mark the location of underground water mains. This tape helps prevent damage that could lead to water contamination or supply disruption.

- Communication Cable Marking Tape:

This tape marks the location of buried communication cables, such as telephone or fiber optic lines. It is typically orange or blue and includes clear warnings to avoid cutting or damaging the wires.

- Customizable Detectable Tape:

For projects with specific requirements, customizable detectable warning tape is available. This tape can be printed with custom text, colors, and logos to meet the unique needs of a project.

How to Use Detectable Warning Tape

Using detectable warning tape is straightforward, but there are best practices to ensure maximum effectiveness:

- Proper Placement:

The tape should be placed directly above the utility line and buried at a depth that ensures it will be detected before any digging reaches the utility. Typically, the tape is placed 12-18 inches below the surface, depending on the depth of the utility.

- Correct Labeling:

Ensure that the tape is clearly labeled with the type of utility it marks (e.g., “Gas Line Below,” “Electric Line Below”). The lettering should be bold and easily readable.

- Continuous Coverage:

The tape should be laid in a continuous strip, without gaps, to ensure that the entire length of the utility is marked. Overlapping the ends of rolls slightly can help maintain continuity.

- Use in Conjunction with Other Safety Measures:

While detectable warning tape is highly effective, it should be part of a broader safety strategy, including accurate utility maps, proper training for workers, and metal detectors before digging.

Benefits of Using Detectable Warning Tape

Investing in detectable warning tape offers numerous benefits, including:

- Enhanced Safety:

The primary benefit of detectable warning tape is increased safety for workers and the public. By clearly marking the location of underground utilities, the tape helps prevent accidents and injuries.

- Cost Savings:

By preventing accidental damage to utilities, detectable warning tape can save companies significant amounts of money in repair costs, project delays, and legal liabilities.

- Compliance with Regulations:

Using detectable warning tape helps ensure compliance with industry regulations, avoiding fines and legal issues. It also demonstrates a commitment to safety and best practices.

- Easy Detection and Identification:

The metallic strip in detectable warning tape allows for easy detection with metal detectors, ensuring that utilities can be located quickly and accurately before excavation begins.

- Versatility:

Detectable warning tape is versatile and can be used for various applications, from marking electrical lines to gas pipelines and communication cables.

Choosing the Right Detectable Warning Tape

When selecting detectable warning tape, consider the following factors:

- Type of Utility:

Choose the tape specifically designed for the type of utility you need to mark (e.g., electrical, gas, water). Ensure that the tape is clearly labeled and color-coded according to industry standards.

- Environmental Conditions:

Consider the environmental conditions where the tape will be used. If the area is prone to moisture, chemicals, or extreme temperatures, choose a tape that is durable and weather-resistant.

- Length and Width:

Select the appropriate length and width of the tape based on the size of the project and the depth at which the utilities are buried. Wider tape may be necessary for larger utilities or deeper burial depths.

- Compliance Requirements:

Ensure that the tape meets all relevant industry and regulatory standards. This may include specific color coding, labeling, and material requirements.

Conclusion

Detectable warning tape is essential for any construction, utility, or excavation project. Its high visibility, durability, and ease of detection make it ideal for marking underground utilities and preventing accidents. By investing in it, companies can enhance safety, ensure compliance, and reduce project costs.

Whether working on a large-scale construction project, maintaining public utilities, or being involved in environmental remediation, detectable warning tape is a wise investment that pays off in safety, efficiency, and peace of mind.

Explore our range of high-quality detectable warning tapes at System Care Printing for all your safety and marking needs. Contact us today to learn how we can help you keep your projects safe and compliant.

Add comment